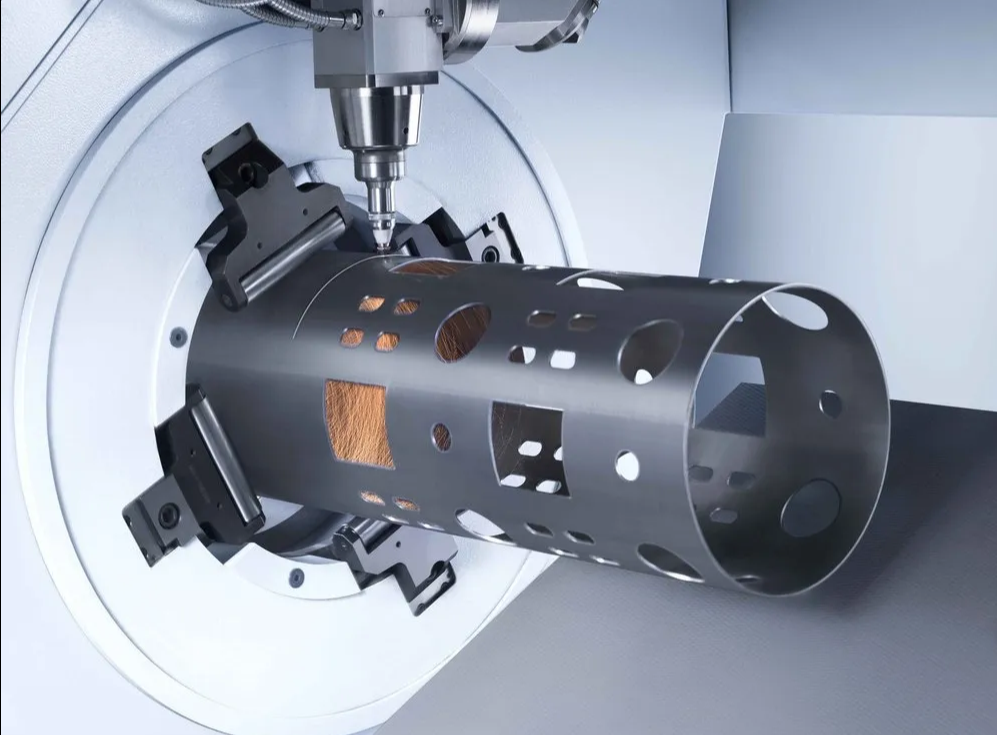

Our Tube Laser processing eliminates the need for traditional methods such as sawing, drilling, and deburring, streamlining production workflows. Compared to conventional tube cutting, lasers integrate multiple steps into a single process, delivering precise cuts and enabling the creation of complex contours in materials like mild steel, stainless steel, aluminum, and nonferrous metals. This advanced technique not only enhances precision but also offers expanded design possibilities, paving the way for innovation in products.

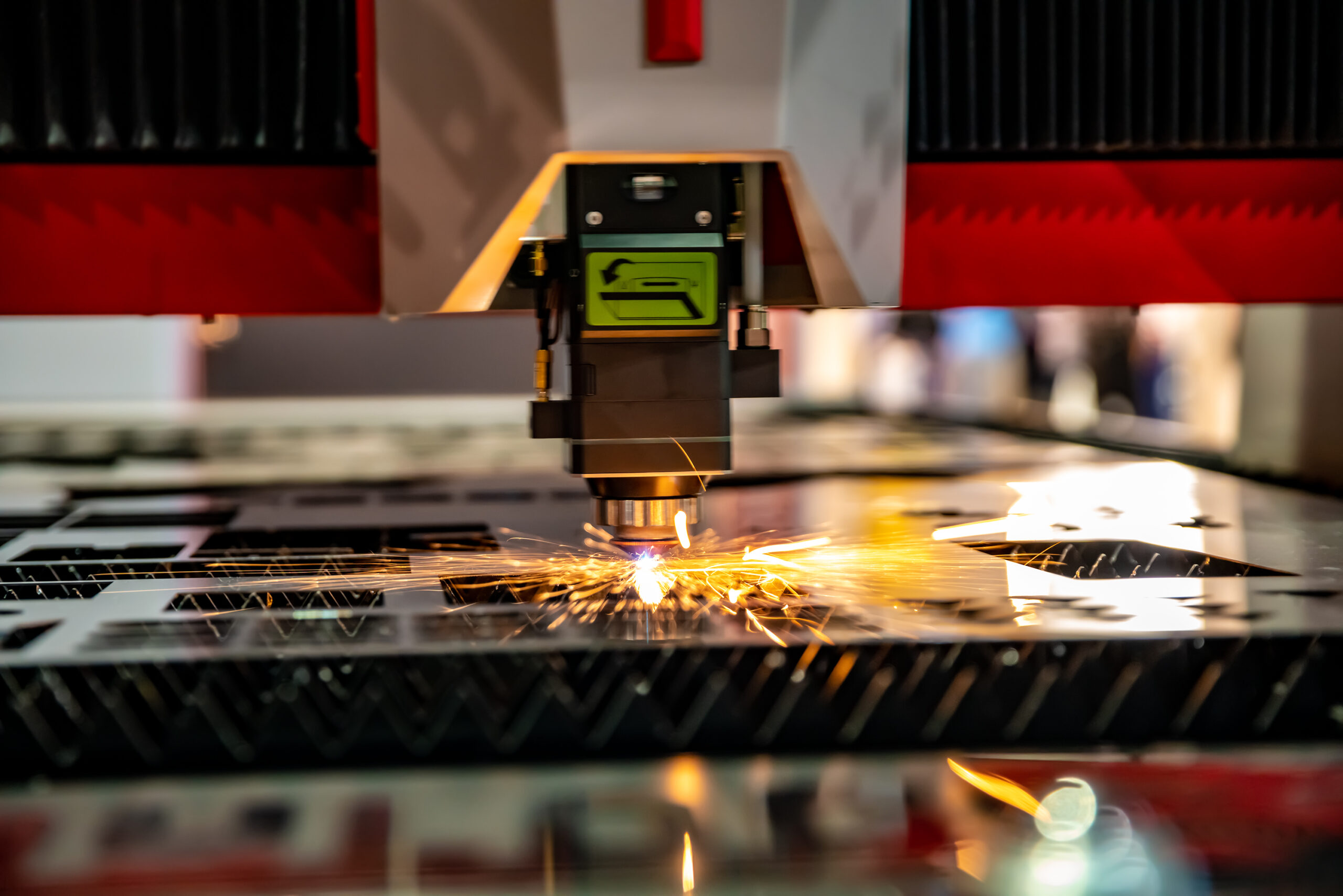

Flat Laser Cutting

At Tru-Cut Metalworks, our flat laser cutting technology delivers clean, accurate cuts across a wide range of materials and thicknesses—up to 6′ x 12′ sheet sizes and 1″ thick. Tied to automated Storage Towers and Part Picking automation we have the capabilities to process parts 24/7 without Human Intervention paving the way to Industry 4.0. Whether you’re working with mild steel, stainless, aluminum, or specialty metals, our lasers provide exceptional edge quality and tight tolerances.

Learn More

Accurate, Repeatable Bends for Any Project

Press Brake Forming

At Tru-Cut Metalworks, our high-performance press brakes deliver precise and repeatable bends across a wide range of materials and profiles. With a maximum bend length of 14′ and 230 US tons of press force, we can accommodate everything from small, intricate components to large-scale industrial parts with ease.

Learn More

“Precision-crafted metal solutions, For those who need Precison And Quality.”

~ Tru-Cut Metalworks

From Concept to Cut—We’re Here to Help

Design Support

At Tru-Cut Metalworks, we’re committed to helping you bring your ideas to life. Our skilled programming team works closely with you to optimize your part designs for laser cutting and forming, ensuring greater efficiency and precision.

Whether you have production-ready files or need assistance developing your concept, we’re here to support you—every step of the way. With our advanced software and innovative machinery, turning your ideas into finished parts has never been easier.