Tru-Cut Metalworks LTD.: Precision in Laser Tube Cutting

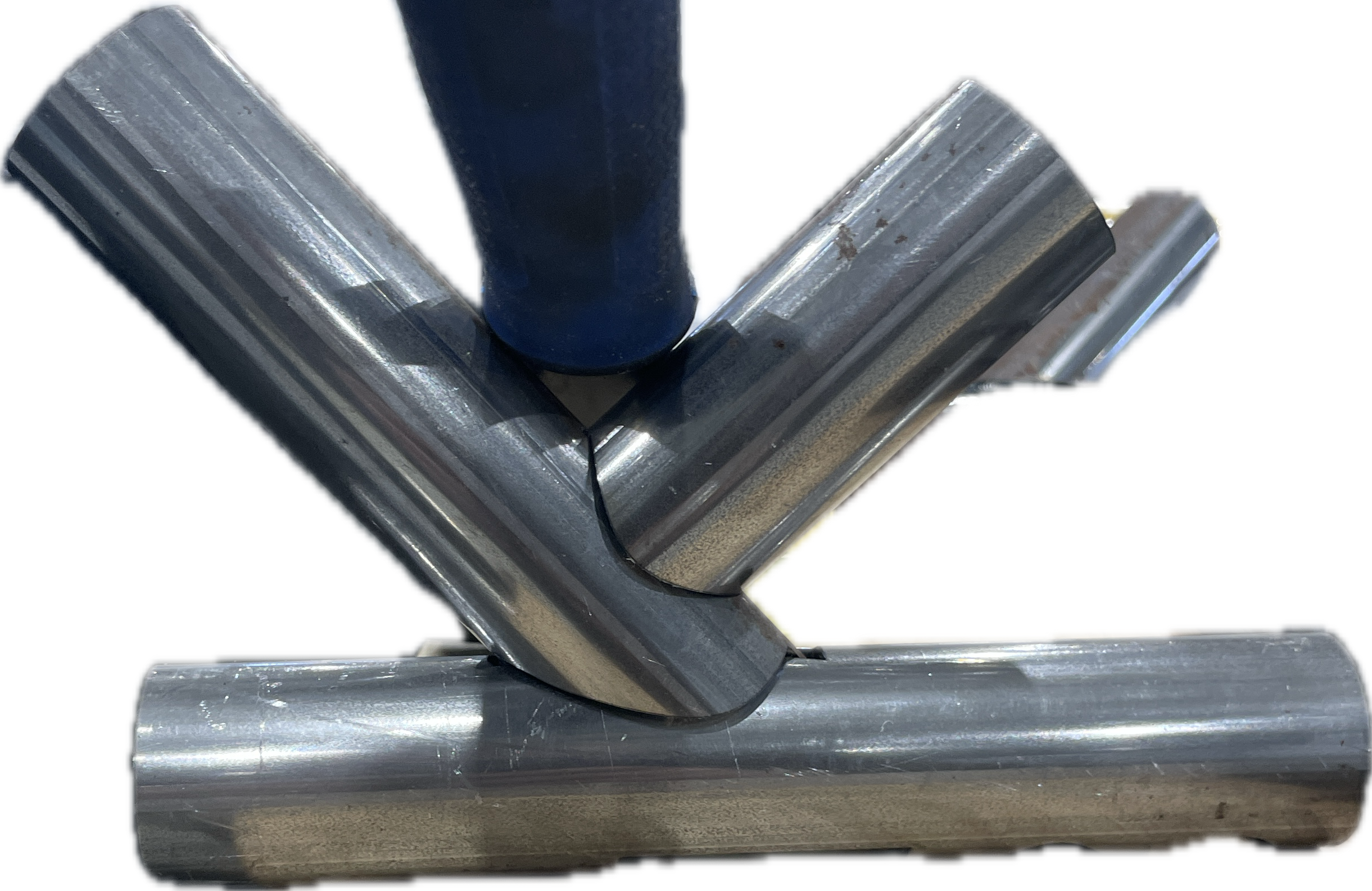

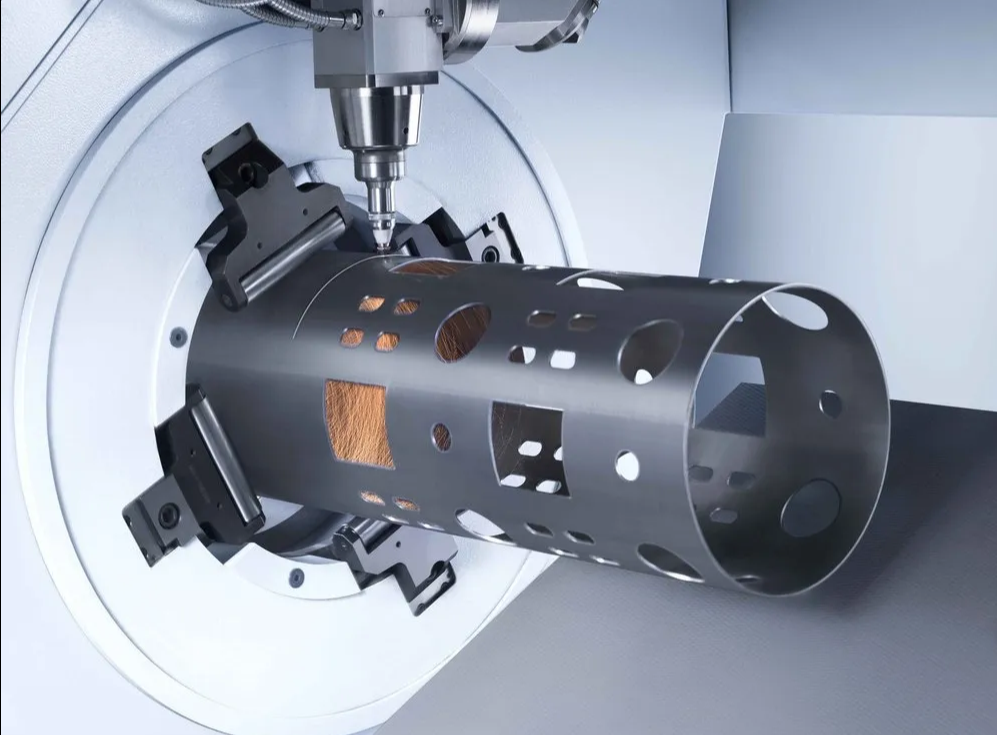

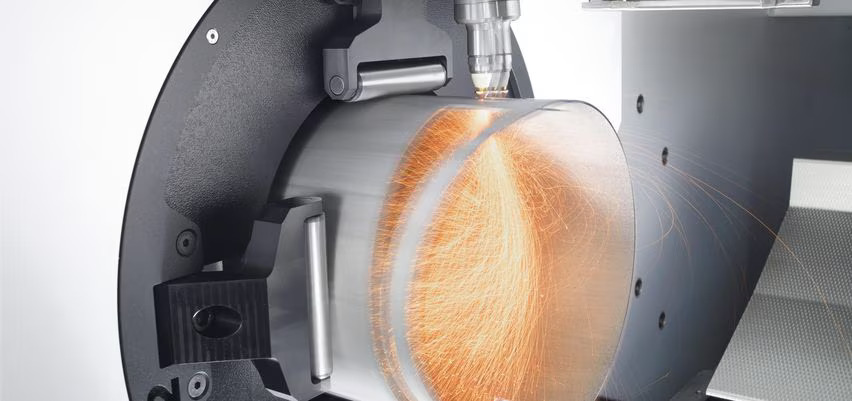

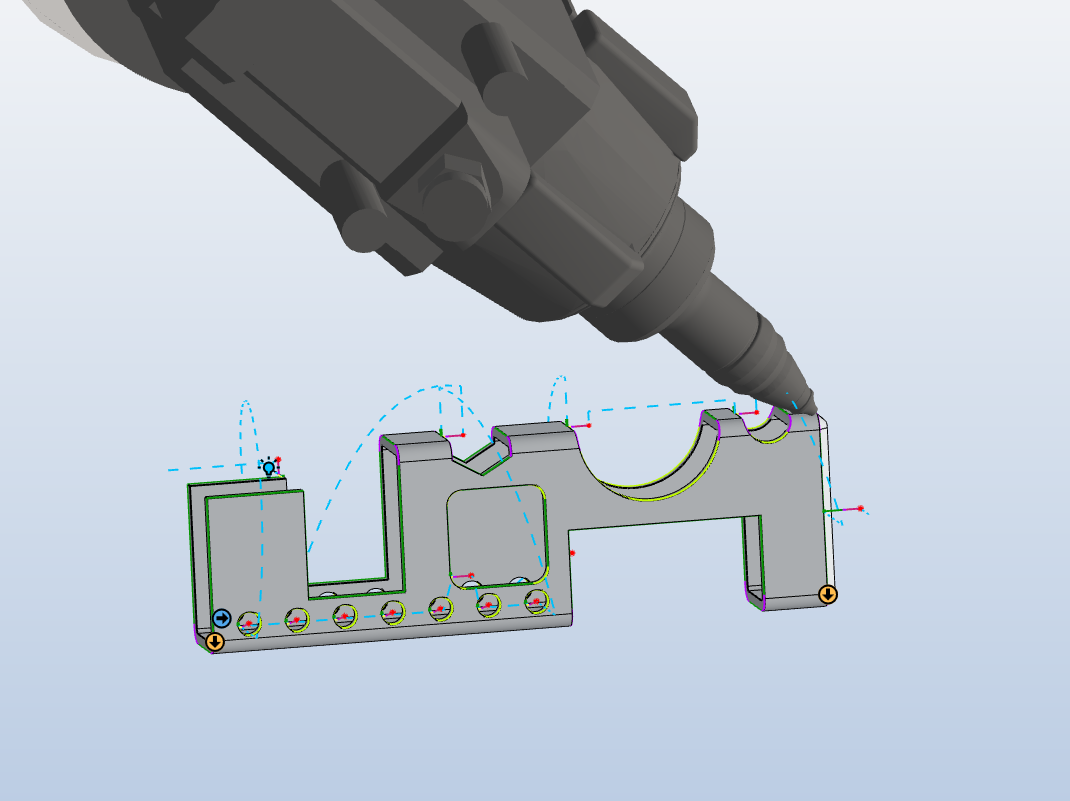

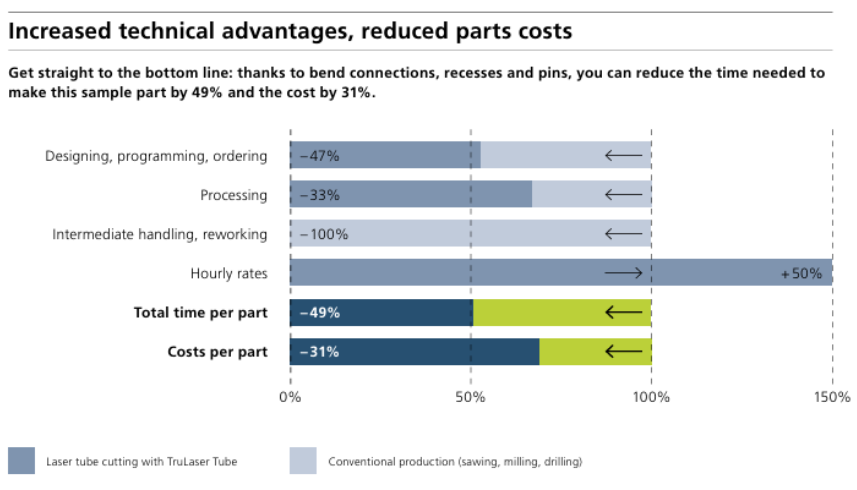

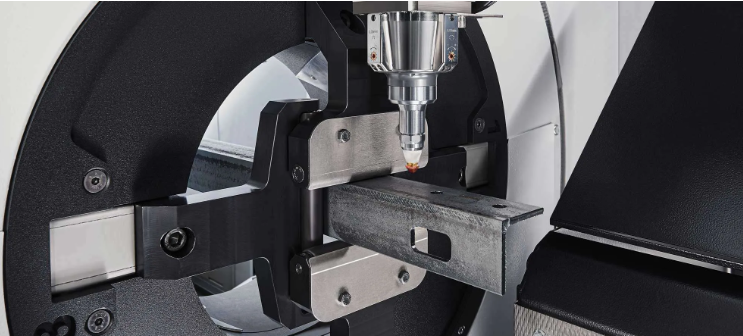

At Tru-Cut, we excel in advanced laser tube cutting solutions for a variety of sizes and profiles.

We pride ourselves on delivering clean, precise cuts that reduce material waste and ensure quick turnaround times. Whether your project involves intricate designs or large-scale production, our reliable process guarantees consistent, high-quality results.

Request Quote

MATERIALS & PROFILES

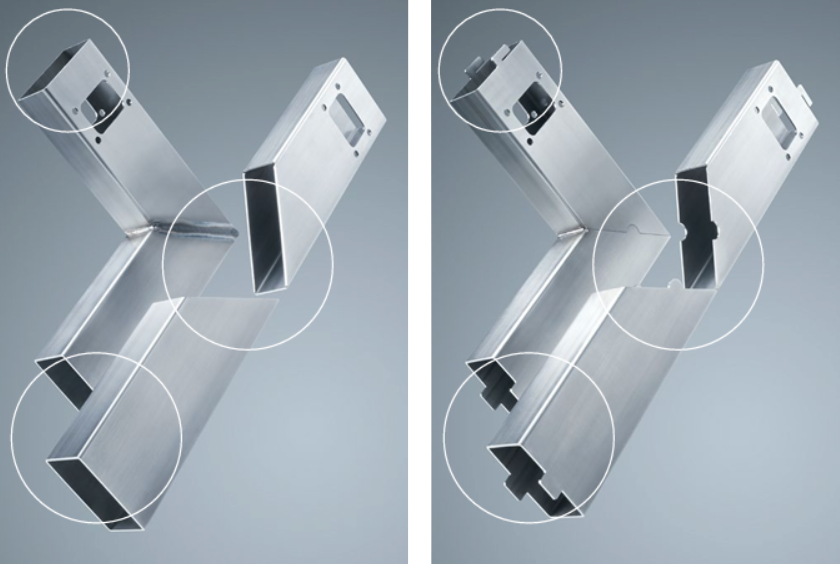

Round – Oval

Square – Rectangle